11.04.2025 by Viktor Siebert

Repair of Discontinued Yaskawa AC Servopack

Is Repair Still Worth It?

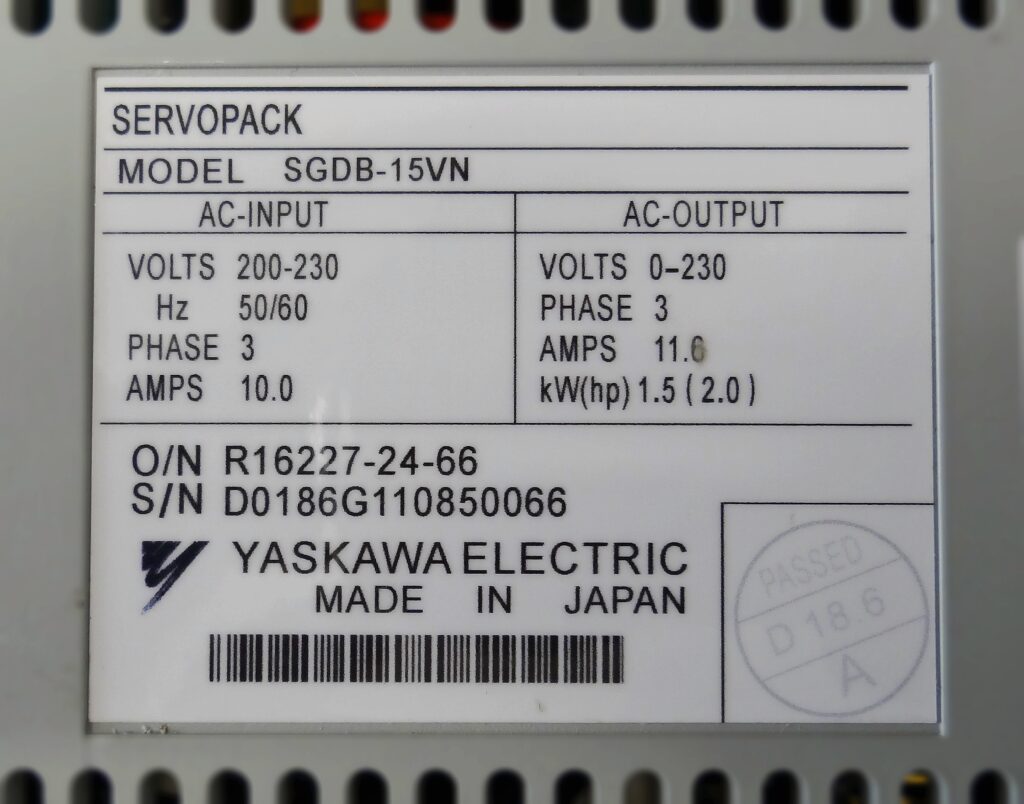

“Is repair still worthwhile?” a customer urgently asked us (Yaskawa Servopack SGDB-15VN), needing a quick solution. He operates a complex multi-axis machine with two spindles, six axes, and tool changers, equipped with a total of eight servos and two spindle modules.

Retrofit vs. Repair – A Tough Decision

Initially, a retrofit seemed the obvious choice. Our customer sought quotations from the machine manufacturer as well as alternative providers. The retrofit required the replacement of motors, drives, controllers, and cabling. Given the machine’s large size and specialized applications, the cost of a comparable new machine would have exceeded half a million euros. Switching to a new machine would also have required significant retraining for the workforce, which was already scarce.

Additionally, retrofitting would have meant about four weeks of machine downtime. The offers he received ranged around €70,000 from the manufacturer and €45,000 from an alternative supplier.

The Solution: Repairing the Servo Drives

Just before finalizing the decision for a retrofit, the customer received a crucial tip: Why not repair instead? Initially skeptical because Yaskawa had discontinued the Sigma 1 series ten years ago, he eventually came to us.

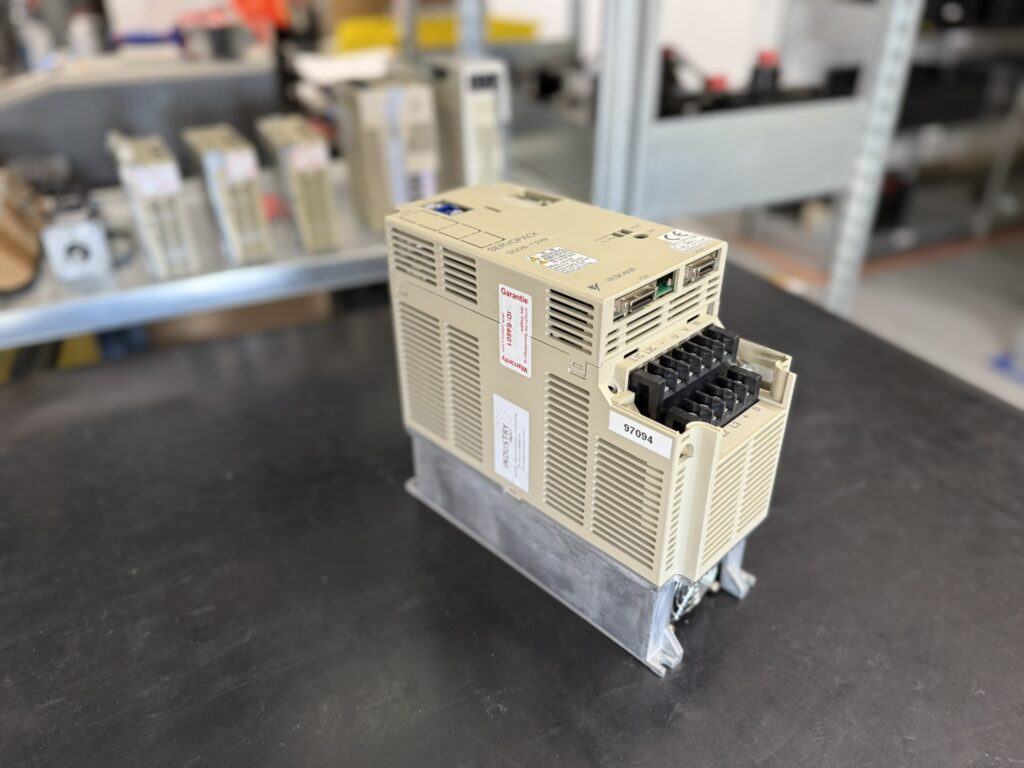

We successfully repaired his Yaskawa AC Servopack SGDB-15VN within just four working days, thanks to standardized repair procedures established for this device generation. Within five days, his production resumed full operations, allowing him to meet his order deadlines.

Convinced by the benefits of repair, he decided to have all motors and drive modules refurbished by us during the summer holidays. This decision cost him only a third of the retrofit price.

Sustainability and Economic Efficiency

Our customer’s decision aligns perfectly with our philosophy: “We don’t just replace; we extend the lifespan—not just for cost savings, but also for the environment.” Sustainable management isn’t just economically prudent; it’s also a vital contribution to environmental protection.

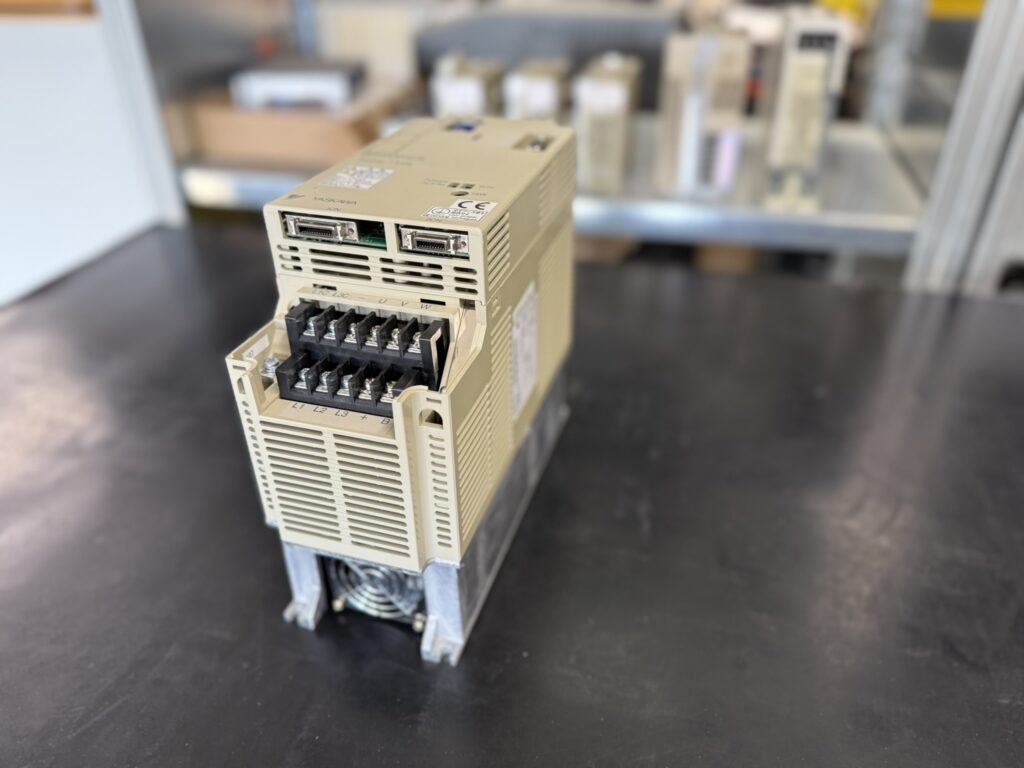

Work Performed on the Yaskawa SGDB-15VN Servopack:

- Comprehensive cleaning and visual inspection of the device.

- Replacement of defective and worn components, especially capacitors, power modules, and cooling fans.

- Complete functional testing and load tests to ensure optimal performance.

The SGDB-15VN Servopack was initially developed to provide precise and dynamic control of servo motors in industrial applications. Main functions include speed, torque, and position control, making it ideal for use in CNC machines, machine tools, and automation systems.

Similar models: SGDB-15AN

For more information about our Yaskawa repairs, please click here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our experienced team is ready to assist you.