02.04.2025 by Viktor Siebert

What Defines a High-Quality Servo Motor Repair?

A practical example: Yaskawa SGMSH-20DCA6H-OY AC Servo Motor.

When a servo motor begins to fail after many years of industrial use, what’s needed is not just a quick fix—but a precise, high-quality repair. In this article, we’ll walk you through a real-life case to show what truly matters during a professional motor overhaul—clear, traceable, and straight from the workshop.

The Case: Yaskawa SGMSH-20DCA6H-OY, Manufactured in 2010

We recently received a Yaskawa AC servo motor SGMSH-20DCA6H-OY for repair. The motor, around 15 years old, showed several issues:

- Stiff movement

- Loud grinding noises

- AL.84 error message on the servo drive

After initial intake, the motor was connected directly to our test stand using the matching Yaskawa Servopack SHDH-20DE (400V). The reported faults were clearly confirmed under real operating conditions.

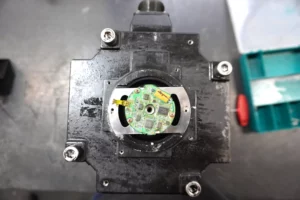

Disassembly & Analysis by the Expert

The proper disassembly was carried out by our experienced motor repair Expert, Mr. P. Glenz. His findings:

- Defective bearings

- Worn-out brake—no brake pad left

- Damaged encoder: fine brake dust had entered the encoder, destroying the encoder glass and bearings. The encoder lost synchronization and repeatedly dropped the connection to the drive.

Many service companies would have considered this a total loss. We didn’t.

Why We Could Help

We specialize in exactly these Yaskawa models. Thanks to our extensive parts inventory and fast access to OEM components, we were able to act immediately. The customer received a detailed quote and approved it without hesitation.

The Repair Process at a Glance

- Mechanical Refurbishment:

All parts were sandblasted, cleaned in our BioCircle system, and dried in a specialized oven.

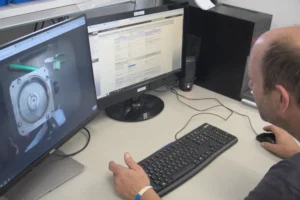

- Sourcing & Programming:

A new brake and a compatible encoder were ordered. Crucially, the encoder was programmed precisely for this motor’s serial number and type.

Why? Because encoder recognition is managed by the servo drive—and in many machines even by the CNC controller. Incorrect encoder data can lead to system failures or non-recognition.

- Reassembly & Testing:

After two days, the motor was mechanically preassembled:

- New bearings

- New seals

- Prepared for brake and encoder

- On day three, the missing components were installed Brake RNB 08.G-60 or RNB08.G-60 DC-24V & Encoder UTSIH-B17CK. The completed motor was tested again:

- Noise levels

- Run-out accuracy

- Current draw

- Insulation strength

- All results were documented by repair shop Manager Mr. S. Kinzig using specialized measuring equipment. A test report can be provided to the customer on request.

- Final Steps:

The motor was freshly painted, underwent a final inspection, and was ready for dispatch after just four working days.

Conclusion: Quality Means Understanding, Acting, and Documenting

This example demonstrates:

- We work honestly, transparently, and fast

- We know exactly what we’re doing and have direct access to the right parts and tools

- We offer high quality—at a fair price

If you’re looking for a reliable repair partner for Yaskawa servo motors:

Get in touch. We’re ready to help.

Here is the product page on our website:

Yaskawa SGMSH-20DCA6H-OY AC Servo Motor

To the matching Encoder: UTSIH-B17CK Yaskawa Encoder

To the matching Brake: RNB 08.G-60 or RNB08.G-60 DC-24V

For more information about our Yaskawa SIGMA II Motor repair services, visit: Yaskawa Sigma II Motor

To the matching drive: Yaskawa SGDH-20DE-OY AC Servopack

📞 Feel free to reach out if you have any questions regarding your Mitsubishi servo motors or drives. Our team is here to help.